With their core advantages of high efficiency, low noise, and long service life, brushless motors have gradually replaced traditional brushed motors to become the mainstream drive solution for small water pumps. Unlike brushed designs, brushless motors use electronic commutation, completely eliminating spark wear, achieving a lifespan of tens of thousands of hours, and improving efficiency by over 30%. However, if the wrong model is selected, the motor is overloaded, or adequate protection mechanisms are lacking, even high-performance brushless motors can still face risks of burnout due to overheating, short circuits, and other issues.

Risk: Sudden voltage fluctuations—such as lightning-induced surges, instant voltage spikes when switching the power supply, or unstable output from an adapter—and sudden load increases (e.g., pipeline blockage) can push current beyond its limit, causing winding temperatures to spike.

▶ Built-in overvoltage, undervoltage, and overcurrent protection chips with a response time as fast as under 10 ms (customizable to customer requirements);

▶ Supports custom wide voltage input from 6 V to 32 V, compatible with multiple power supply systems, effectively reducing the risk of pump damage caused by voltage fluctuations.

Scenario 2: Stall or Dry-Run Out of Control

Risk:Loss of medium or foreign object blockage can cause the motor to stall, with current instantly exceeding five times the rated value.

▶ Intelligent stall detection algorithm that automatically shuts down the pump within 1 second of rotor seizure;

▶ High-precision, one-piece injection-molded rotor with dynamic balance ≤30 mg, reducing the risk of jamming and vibration at the source.

Hig-precision injection molded rotor dynamically balanced

Scenario 3: High Temperature and Corrosive Damage

Risk:Poor heat dissipation or chemical corrosion can cause insulation failure, leading to short circuits.

▶ Electronic zoning layout + German-imported adhesive + automated mixing and potting technology: blocks liquid penetration paths, creating a highly reliable sealing barrier that effectively prevents fluid ingress and corrosion, while enhancing electrical insulation and thermal stability;

▶ High-temperature-resistant imported components rated to 125 °C + housing made from heat- and corrosion-resistant materials: ensures stable operation in ambient temperatures up to 80 °C and liquid temperatures up to 105 °C.

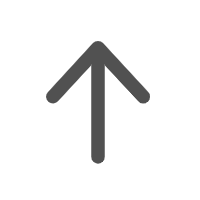

Water pump parts and electronic components

Scenario 4: Cumulative Mechanical Wear

Risk:Bushing wear or rotor misalignment can cause frictional heating, leading to continuous efficiency loss.

▶ High-wear-resistant imported graphite bushings:capable of continuous operation for 3,000 hours in temperatures above 95 °C, with key dimensional wear of less than 0.02 mm;

▶ High-precision injection molding process: improves rotor concentricity and structural stability, effectively reducing operating noise and mechanical wear.

Graphite bushings and rotors

TOPSFLO Brushless Pumps — Advancing from Protection to Evolution

Going beyond basic safeguards, TOPSFLO three-tier Prevention–Control–Optimization technology framework redefines miniature pump reliability:

• Prevention Layer: IP68 protection + anti-corrosion coating to shield against environmental damage.

• Control Layer: Multi-sensor real-time monitoring of voltage, current, and temperature, with instant feedback to the control chip.

• Optimization Layer: Constant-power output technology that automatically adjusts motor operation according to load changes, ensuring stable performance, reducing overload risk, and extending overall service life.

• Comprehensive Validation: Products undergo rigorous reliability testing, including -40 °C to 100 °C thermal cycling, salt spray, electronic temperature rise, overvoltage, and overcurrent tests—ensuring they meet the stringent requirements for high reliability and long service life across diverse industries.

• Compliance Assurance: Certified by TÜV Rheinland for both ISO 9001 and IATF 16949 quality management systems, fully covering industrial and automotive-grade standards. Holding multiple international certifications such as FDA, WRAS, CE, RoHS, and REACH, meeting regulatory requirements for drinking water and medical equipment applications.

• High-Performance Guarantee: Leveraging precision structural design and proven manufacturing expertise, TOPSFLO brushless pumps excel in stability, efficiency, and durability—widely used in performance-critical sectors such as medical, automotive, drinking water, and new energy.

TOPSFLO Brushless Pumps — Making Motor Burnout a Thing of the Past.

Contact our engineers today for a customized pump selection report and a pre-diagnostic failure analysis plan.

Recommend you also directly send and email to info@topsflo.com to get our fastest response.

Recommend you also directly send and email to info@topsflo.com to get our fastest response.