As range anxiety in new energy vehicles gradually eases, charging time has become the new focus. Ultra-fast charging technology that offers “5 minutes of charging for 200 km of range” has emerged. However, the unsung heroes behind this lightning-fast speed are the powerful power modules and charging cables inside the charging piles. During high-speed operation, they generate tremendous heat. If not dissipated in time, this can reduce efficiency at best, or cause malfunctions and even safety incidents at worst. Thus, two major cooling technologies have quietly taken the stage: liquid cooling for modules and cooling for charging cables. How do they work, and what are the differences?

The “Heart” and “Blood Vessels” of Charging Piles: Power Modules and Charging Cables

What is a “Power Module”?

The power module is the “heart” of a DC charging pile. Its core function is to convert grid alternating current (AC) into direct current (DC) required by electric vehicle batteries. It also acts as the “engine” for power output. The output power (kW) of a charging pile directly depends on the performance and quantity of the power modules. A single module typically has a power rating of 15kW, 20kW, 30kW, 40kW, or even higher. To achieve high-power fast charging (e.g., 150kW, 350kW, 600kW), multiple power modules are connected in parallel inside the charging pile to work together.

The power module contains complex control circuitry. It needs to communicate in real-time with the vehicle’s Battery Management System (BMS), dynamically adjusting the output voltage and current based on the battery’s status (voltage, temperature, State of Charge – SOC) to ensure an efficient and safe charging process, preventing overcharging or battery damage.

Image: Source Internet

What is a “Charging Pile Cable”?

The charging pile cable is the core specialized equipment that supplies electrical energy to Electric Vehicles (EVs) or Plug-in Hybrid Electric Vehicles (PHEVs), acting as the “lifeline” between the charging pile and the electric vehicle.

Its core functions and features include:

1. Transmitting High-Power Electrical Energy: The cable contains multiple thick conductors (typically copper) specifically designed to safely and efficiently transmit the high current and voltage required for charging.

2. Control Signal and Data Communication: The cable also contains thin wires for low-voltage signal transmission. These signal lines are responsible for establishing “communication” between the charging pile and the vehicle, transmitting Control Pilot (CP) signals and communication data (e.g., CAN or PLC).

3. Safety Assurance: The cable employs insulation protection and ensures safe charging through measures like temperature monitoring, mechanical protection, and interface protection.

Image: Source Internet

Why Do Charging Pile Power Modules and Cables Need Cooling Systems?

1. Power Module Cooling

The internal components of power modules are densely packed. The efficiency of electrical energy conversion is about 95~98%, leading to highly concentrated heat generation. The lost energy is released as heat. For instance, a 150kW pile can generate 3~7.5kW of heat. Temperature requirements are extremely strict, typically needing to be controlled below 85°C.

Liquid cooling is currently the mainstream solution for high-power charging piles (especially those above 150kW). Its core principle involves coolant circulating at high speed within sealed flow channels, directly contacting heat sources inside the module or passing through heat dissipation substrates to efficiently carry away heat. The heat is then dissipated into the environment via an external radiator (air-cooled or secondary liquid-cooled). Liquid cooling offers significant advantages: high heat dissipation capacity, uniform and precise temperature control, and high reliability.

2. Cable Cooling

The core goal of cable cooling is to resolve the conflict between “high-current transmission” and “ease of handling.” When current flows through a conductor (the copper/aluminum cores inside the cable), heat (Joule heat) is generated due to the conductor’s resistance, according to the formula: Q=I²RT. The larger the current, the greater the heat generated—increasing quadratically! The heat generated by transmitting 500A or 600A currents is far beyond what a standard cable can withstand.

Cable cooling technology allows for the safe transmission of ultra-high currents with limited or even no increase in cable cross-sectional area through active heat dissipation, thereby achieving “lightweight” and “flexible” cables. Its cooling solutions must balance heat dissipation efficiency and structural design. There are two main types:

Liquid-Cooled Cables: These are the essential choice for current ultra-high-power fast charging. Besides the traditional conductive cores, they include an independent internal tube where coolant circulates, directly carrying away the heat generated by the cable. This allows the cable to remain relatively slim and flexible even while carrying larger currents.

Air Cooling/Natural Cooling: Primarily used in charging piles with relatively lower power (e.g., 60kW and below). They rely on natural air convection or small built-in fans for forced convective heat dissipation. The advantage is simple structure and low cost, but heat dissipation capacity is limited under high currents, often requiring thicker and heavier cables to reduce resistive heating.

| Liquid-Cooled Power Module | Charging Cable Cooling | |

| Core Purpose | Cool power conversion components inside the charging pile | Cool the charging cable transmitting high current |

| Cooling Target | Heat-generating cores like IGBT/SIC modules | Conductor within the charging cable |

| Key Technology | Sealed liquid cooling circulatory system (pump, tubing, cold plate, radiator) | Enables high-current transmission while making the cable lighter, thinner, and more flexible, improving user experience |

| Key Advantage | Extremely high heat dissipation power,supports ultra-high power, long duration operation; relatively compact module size | Enables high-current transmission while making the cable lighter, thinner, and more flexible, improving user experience |

| Application | Foundation for achieving ultra-high power output from charging piles | Key to achieving safe and convenient transmission of ultra-high currents |

| Interrelationship | Typically used together! Liquid-cooled modules enable high-power output, while cooled cables ensure this high current can be delivered to the vehicle safely and comfortably. | |

The “Cooling Engine”: The Core Driving Role of Liuqid Pumps

In the realm of ultra-fast charging for new energy vehicles, “liquid cooling” has become a critical technology for enabling high-power charging. Whether for the power modules inside charging piles or the charging cables connected to vehicles, an efficient liquid cooling system relies on a core power source—the EV Charger Pump. Functioning as the “heart” of the liquid cooling system, the liquid cooling pump drives the circulating flow of coolant, effectively drawing heat away from key components.

When a charging pile operates at high power (e.g., above 350kW), components such as power modules generate substantial heat. If not dissipated promptly, this heat can lead to overheating damage, reduced charging efficiency, or even trigger overheat protection mechanisms. The liquid cooling pump plays a vital role by pumping low-temperature coolant from the reservoir into the heat exchanger. There, the coolant absorbs heat and becomes high-temperature coolant before flowing through a radiator (or external cooling tower) to dissipate the heat. Finally, the coolant cycles back into the charging pile, forming a closed-loop cooling system. Additionally, the pump ensures sufficient coolant flow rate across heat-generating areas, enabling efficient heat exchange. It also maintains stable system pressure to guarantee effective coolant contact with heat dissipation surfaces.

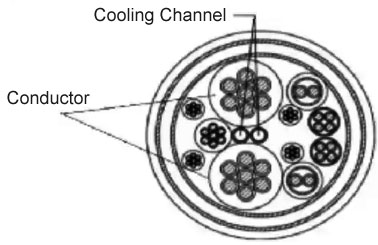

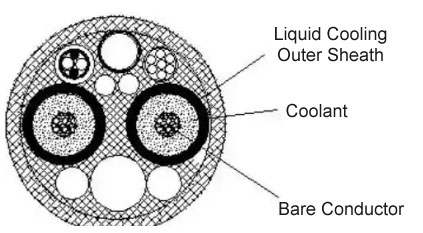

The cooling principle of liquid-cooled charging cables involves integrating liquid cooling channels within the cable structure. The liquid cooling pump circulates coolant to remove heat generated by the cables. Liquid cooling terminals are categorized into two technical approaches based on the cooling medium: water cooling and oil cooling. In current designs using a water-refrigerant medium, liquid cooling pipes are positioned alongside the DC+/DC- conductors to extract heat from the copper conductors. For designs using insulating oil as the medium, the liquid cooling tubes are placed either inside or outside the DC+/DC- cores to achieve the same heat dissipation effect. For detailed illustrations, please refer to the following structural diagrams.

|

|

|

| Figure 1: Structure using Water + Refrigerant Liquid Cooling | Figure 2: Structure using Insulating Oil Coolant Liquid Cooling |

TOPSFLO Micro Pumps: Enabling Efficient and Safe Ultra-Fast Charging

In an era pursuing higher power and faster charging speeds, a high-performance and highly reliable fast EV charger pump serves as the cornerstone for the stable operation of charging pile cooling systems. TOPSFLO Micro Pump Company has developed a series of high-performance cooling water pumps specifically for electric vehicle charging applications, suitable for both power module cooling and cable cooling.

What type of pump is ideal for power module cooling?

TOPSFLO’s TL series brushless DC centrifugal pumps, with their three core advantages—high efficiency, quiet operation, and extended lifespan—have become the preferred cooling solution for leading global charging pile manufacturers.

1. Brushless Motor Design: Eliminates brush wear entirely, enabling maintenance-free operation for up to 30,000 hours.

2. Robust Materials and Precision Engineering: Key components are constructed from high-temperature and corrosion-resistant materials, rigorously tested to ensure reliable performance under the demanding conditions of 24/7 charging pile operation.

3. Intelligent Control: Precisely matches cooling demands, improving efficiency by 30% compared to traditional pumps while maintaining noise levels below <45 dB (measured at 1 meter), meeting quiet deployment requirements in urban residential areas.

What type of pump is suitable for charging cable cooling?

Addressing the stringent challenges of confined spaces, frequent bending, and high pressure in ultra-fast charging pile liquid-cooled cables, TOPSFLO’s MG series micro gear pumps stand out as the industry’s top choice due to their innovative design:

1. Premium Material Selection: Features a 316L stainless steel housing, with gears and bearings made from high-performance specialty PEEK material. Gear shafts are crafted from precision industrial zirconia ceramics, offering exceptional hardness, temperature resistance, wear resistance, corrosion resistance, and longevity.

2. Superior Performance: The TOPSFLO MG317 series micro magnetic gear pump, equipped with a 24V 150W DC brushless motor, delivers a service life exceeding 20,000 hours. It operates in ambient temperatures ranging from -35°C to 55°C, handles fluid temperatures from -40°C to 85°C, and provides a flow rate of 0.75–6 L/min with an output pressure of 0–6 Bar.

3. Comprehensive Protection: The motor boasts an IP67 protection rating, supports standard 0–5V speed regulation, and can be customized with PWM signal speed control. It includes bidirectional rotation control, 150W power limit protection, 125°C controller over-temperature protection, stall protection, and other multi-layered safety features.

Choosing TOPSFLO micro pumps means choosing a powerful, quiet, and reliable “cooling heart” for your charging pile. We are committed to providing excellent fluid solutions to dissipate the heat wave at the core of charging, ensuring the safe and efficient transmission of every kilowatt-hour, and jointly accelerating the arrival of the electric vehicle era!

Recommend you also directly send and email to info@topsflo.com to get our fastest response.

Recommend you also directly send and email to info@topsflo.com to get our fastest response.