The increasing popularity of cloud computing, storage, for both home and business, has created a growing demand for highly efficient and extremely fast data centers. The consequence of higher computer processing speeds is the generation of more heat, which is not a good thing for electronics. Previously air-cooled, many data centers are now switching to liquid cooling technology as a more effective method of dissipating computer-generated heat in critical high-tech equipment.

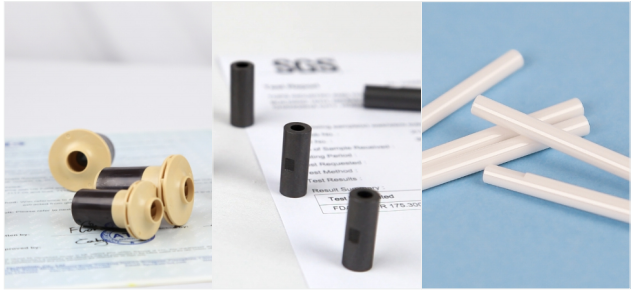

Sealless, motor-integrated centrifugal pumps feature an integrated brushless DC variable speed motor ranging from 12 to 48 volts, integrating components into a compact, lightweight design. Fewer parts facilitate the advantages of no leakage, long life, low noise, low power consumption, and high temperature resistance.

Product customization according to the special needs of customers, support 5V/PWM speed regulation, FG speed signal feedback function, automatic intelligent detection function, support failure alarm, real-time data feedback, etc.

Designed for the circulation and transfer of fluids, TOPSFLO Pumps offer a flexible, safe and robust solution to moving fluid in critical high-tech applications.

Adopting efficient DC brushless motor and rotor design, the flow rate and head fully meet the needs of liquid cooling servers. By directly contacting the liquid medium with the high heat density heat source, the micro pump absorbs and takes away the heat more efficiently, and significantly improves the heat dissipation efficiency of the system.

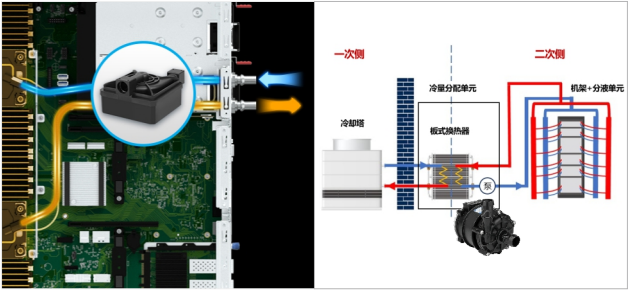

The cooling media used in the data center industry are diverse, including pure water, formula liquid, hydrocarbons, silicone oil, and fluorocarbons (fluorinated liquids). TOPSFLO water pumps have undergone comprehensive compatibility evaluations in the selection of materials for water-related parts, and provide a variety of material options to meet the needs of different customers.

Adopting advanced magnetic drive static seal design and high-quality imported plastic materials, combined with high-precision mold manufacturing, the water pump has undergone strict leakage detection by French high-standard airtightness testing equipment, significantly reducing the risk of leakage and ensuring the safety and reliability of the server system.

Using unique rotor suspension technology, with highly wear-resistant imported graphite sleeves and high-precision ceramic shafts, the water pump performance is stable and smooth, effectively reducing server system failures and downtime.

Water-cooling pump for 1U, 2U and tower server

3U, 4U Server Liquid Cooling Pump

Water-cooling pump of Cooling Distribution Unit (CDU)

The pump for the make-up device of Cooling Distribution Unit (CDU)

Get product catalog, please contact us !

Server & Electronics Liquid Cooling Pump Series by TOPSFLO

Voltage 12VDC

Max Flow 5.8L/min

Max Head 6M

Voltage 24V

Max Flow 42L/min

Max Water Head 30M

Voltage 12VDC

Max Flow 5.8L/min

Max Head 6M

Voltage 12VDC

Max Flow 8.5L/min

Max Head 6M

| Basic market situation

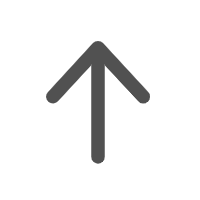

With the advent of the digital age, data center servers have experienced rapid and continuous development and are playing an increasingly important role, providing powerful computing capabilities for applications such as cloud computing, artificial intelligence, and big data. As servers continue to evolve and expand in scale, their processing power and storage capacity continue to increase, and their heat dissipation requirements are getting higher and higher. Traditional air cooling methods can no longer meet the growing heat dissipation needs. In order to solve this problem, server liquid cooling solution emerged.

| Market pain points

There are the following difficulties in implementing a liquid cooling solution in 1U/2U server:

1.The problem of limited design space: The original air-cooling design solution is relatively mature. If you want to add a liquid cooling solution while maintaining the original design solution, the layout space for the liquid cooling solution will be very limited. 1U server Height = 4.445 cm, 2U server height = 4.445*2 = 8.89 cm.

2.Sealing and anti-leakage issues: Liquid cooling systems involve the use of a large amount of liquid media, and the core component in the server is the chip (CPU and GPU, etc.). Once the chip comes into contact with liquid, there is a risk of burning, resulting in The entire server is damaged, so it’s crucial to ensure the fluid circulation system is air-tightness and leak-proof.

3.Heat dissipation efficiency and performance issues: More than 55% of chip failures are caused by heat transfer failure or temperature rise. If the chip is above 70 degrees, its reliability will be reduced by 50% for every 10 degrees of temperature increase. Once the quality of the components in the cooling assembly is not good or the circulation design is not effective, there is a possibility of unstable product performance, which will lead to local overheating or insufficient cooling, thus affecting the normal operation of the server.

| TOPSFLO Solution

In order to meet the needs of cold-plate liquid-cooled servers, Topsflo Pump has specially designed a water pump with a unique flat design for them, which can better solve the problems currently encountered by server manufacturers:

1.The TDC thickness of the micro water pump is as low as 36mm and the overall size is small. The solution of combining the pump and the cold plate can be customized to help save space in the data center. Compared with bulky traditional cooling equipment, the compact design of micro water pumps makes server liquid cooling systems easier to deploy in limited spaces.

2.Water pump static seal design, imported PPS high-quality materials, high-precision molds, 100% strict air tightness testing of the water pump through high-standard air tightness testing equipment imported from France, effectively reducing the risk of leakage to ensure the safety of the server system performance and reliability.

3.Adopt unique rotor suspension technology and select high-wear-resistant imported graphite bushings and high-precision ceramic shafts to resist long-term operation and inevitable wear, ensure stable performance and operating status of the water pump, and reduce server system failures and downtime.

4.According to the heat dissipation requirements of the server, the micro water pump TDC is customized with a maximum flow rate of 8L/min and a maximum water head of 5M. The flow rate and water head are optimized in a compact size to meet the heat dissipation needs of the system. At the same time, the built-in smart chip can customize intelligent speed regulation and signal feedback functions to meet the needs of real-time intelligent monitoring of servers and help achieve more precise temperature control and stability of the server system.

Dive into the Evolution of High-Density Server Liquid Cooling Systems: A Journey through Innovation

Over the years, High-Density Server cooling has witnessed a remarkable transformation. From the early days of simple air-based cooling to the emergence of sophisticated liquid cooling systems, the history of data center cooling is a testament to human ingenuity and the pursuit of optimal performance.

The Birth of Air Cooling:

In the early days of High-Density Server, air cooling reigned supreme. Large air conditioning units pumped chilled air into server rooms, dissipating the heat generated by the high-density equipment. While effective to a certain extent, this method proved inadequate as data center demands grew and server densities soared.

The Advent of Liquid Cooling:

Recognizing the need for more efficient cooling solutions, liquid cooling systems made their entrance. Initially, these systems focused on cooling specific components, such as CPUs or GPUs, using liquid-based heat sinks. This targeted approach provided improved cooling efficiency, allowing for higher computing power in compact spaces.

The Rise of Immersion Cooling:

As Rack Servers faced escalating power densities and limited space, immersion cooling emerged as a game-changer. By immersing server components in a non-conductive liquid, heat dissipation improved significantly. This method showcased unprecedented cooling capabilities, enabling greater energy efficiency and reduced operational costs.

Innovations in Liquid Cooling Technology:

Advancements in liquid cooling technology further revolutionized Rack Servers cooling. Closed-loop systems with cooling pumps, heat exchangers, and coolants circulated liquid directly through server components, efficiently carrying away excess heat. These systems enabled precise temperature control and facilitated rapid heat dissipation, optimizing server performance.

Hybrid Approaches and Future Trends:

As Liquid Cooled Rackmount Server continue to evolve, hybrid cooling approaches combining air and liquid cooling have gained traction. These innovative systems leverage the strengths of both methods, optimizing cooling efficiency while accommodating the unique requirements of different environments.

Looking ahead, the future of Liquid Cooled Rackmount Server cooling holds promising developments. Innovations such as direct-to-chip cooling, where liquid is delivered directly to individual processor chips, and advanced cooling architectures are on the horizon. These advancements aim to maximize cooling efficiency, reduce energy consumption, and enhance the sustainability of Server data center operations.

Today, we stand at the forefront of an era where liquid cooling systems have become integral to modern High-Density Server. They provide the means to tackle the challenges posed by escalating power densities and enable the seamless operation of mission-critical systems.

Experience the Evolution:

Join us on this journey of innovation and transformation. Explore the power of liquid cooling systems and unlock the potential of your High-Density Server. Embrace the history, embrace the future, and elevate your cooling capabilities to new heights.

Contact us today to learn more about our cutting-edge liquid cooling solutions and embark on a cooling revolution. Discover the possibilities that lie ahead and ensure the success of your High-Density Server operations. Together, let’s shape the future of High-Density Server cooling!

Recommend you also directly send and email to info@topsflo.com to get our fastest response.